If you are adding coolant, you have a leak.

Shaler Rink Seal Pro™ is a comprehensive leak-sealing solution for both cold and warm loops in ice rink systems. It effectively seals leaks in polyethylene, copper, and steel piping, and is fully compatible with all major coolants – including ethylene glycol, propylene glycol, and salt brine. The non-toxic formula is safe for the entire system and won’t clog or cause damage. It’s completely harmless to plastics, metals (including aluminum), hoses, and connections, making it a worry-free choice for protecting and maintaining critical infrastructure.

Shaler® Rink Seal Pro™ Key Benefits

- Seals leaks

- Inhibits formation of rust and scale

- Keeps system clean

- Neutralizes pH imbalance

- Controls electrolysis

- Lubricates coolant pumps

- Compatible with ALL types and brands of coolant

- Conditions and enhances refrigeration/heating system operation

Rink-Specific Sealant Technology

The sealing particles in Rink Seal Pro™ adhere to the outer surface of a leak and build inward, creating a flexible seal. As they come into contact with outside air, the particles dry and expand by roughly 15%, forming a smooth, putty-like seal that locks the leak from the outside in – without disrupting system flow.

Pump Seal Lube

Rink Seal Pro™ features a built-in water pump seal lubricator that delivers two key benefits: it helps keep the seal face clean to prevent leaks, and its blend of fine particle sizes acts like graphite, penetrating between the shaft and seal to provide light lubrication – reducing friction, noise (howl/chatter), and wear over time.

Coolant Conditioner

Rink Seal Pro™ conditions the coolant to prevent rust, scale buildup, and the formation of dead or weak zones that reduce system efficiency. It works both chemically and mechanically: chemically, it stabilizes pH levels to help prevent corrosion and electrolysis pitting; mechanically, its particles buff and scrub internal surfaces, removing buildup and enhancing heat transfer. It also functions like a sacrificial anode, offering protective benefits that extend the life of system components.

Improves Heat Transfer

In addition to keeping the system clean – which naturally improves heat transfer – Rink Seal Pro™ uses a blend of particle sizes that increases the effective surface area of the coolant. This enhanced thermal interaction benefits both the chiller loop and the under-ice floor loop. In both new and aging systems, typical results show a 2.5% gain in overall efficiency between the two loops.

ASTM D3147 Laboratory Test

The performance results for Rink Seal Pro™ are based on ASTM D3147 – the industry-standard test method for evaluating stop-leak additives in cooling systems. This testing protocol provides a controlled, repeatable way to assess the effectiveness of leak-stopping materials. Specifically, ASTM D3147 outlines procedures for screening how well a product seals leaks, maintains system integrity, and operates under simulated real-world conditions. Rink Seal Pro™ meets and exceeds the performance benchmarks established by this standard, ensuring proven reliability and performance in demanding cooling and heating loop environments.

| Gum/Gel Before | No |

| Gum/Gel After | No |

| Particles Before | No |

| Particles After | No |

| Screen | 0.51 mm (0.020 inch) |

| Final Round | 0.64 mm (0.025 inch) |

| Final Slot | 0.25 mm (0.010 inch) |

| Fluid Lost, mL | 495 |

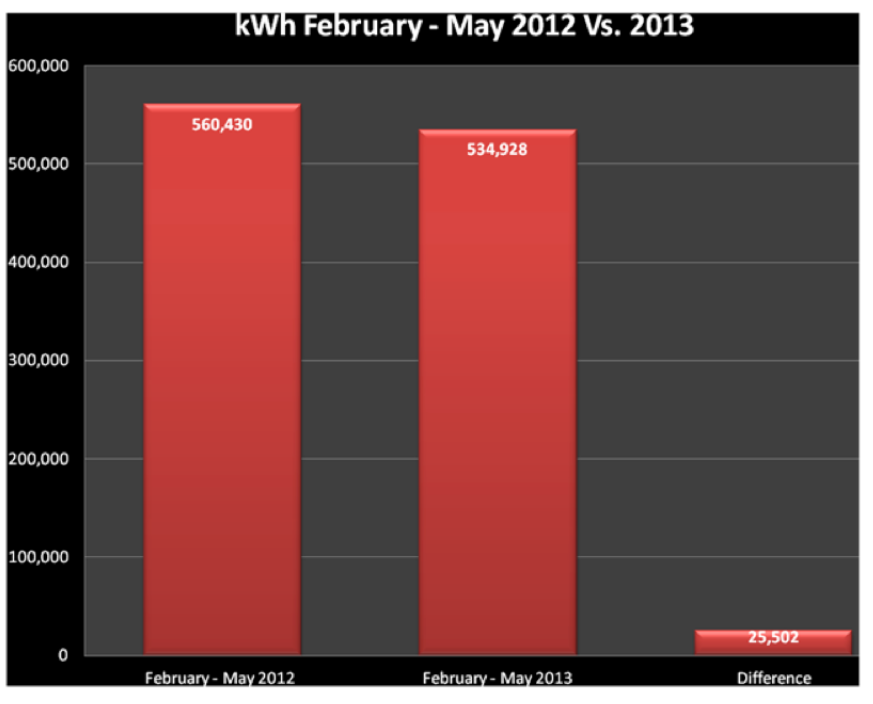

Year-over-Year Energy Consumption (4 Month Period: 2012 vs. 2013)

Despite a 6.9% increase in facility usage across all three ice sheets in 2013, overall energy consumption decreased – demonstrating the measurable efficiency gains achieved after implementing Rink Seal Pro™.

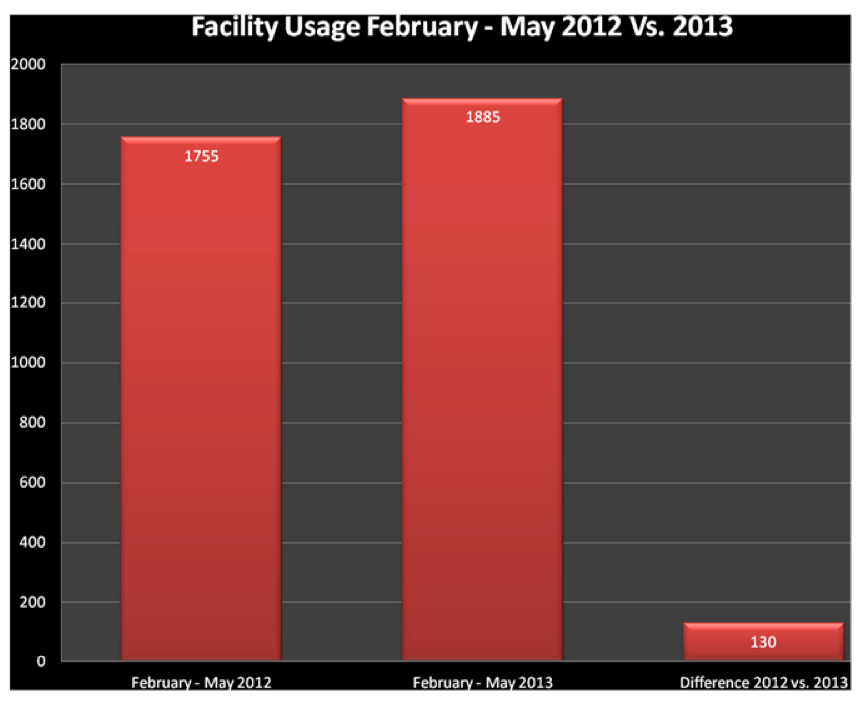

Facility Usage in Hours: 2012 vs. 2013

Even with more hours of operation in 2013, the test facility recorded significant energy cost savings following the installation of Rink Seal Pro™ – a clear indicator of improved system efficiency under increased demand.

Testing confirms that Rink Seal Pro™ can successfully seal leaks as large as a 0.64 mm (0.025 inch) round hole and a 0.25 mm (0.010 inch) wide crack – demonstrating its effectiveness in addressing both pinpoint leaks and narrow fractures common in rink and underfloor systems.