Stop leaks before they stop your operation.

Shaler Industrial Seal Pro™ is a comprehensive leak-sealing solution for both chilled and heated fluid loops in large-scale refrigeration systems. Whether you manage a cold storage warehouse, food processing plant, or industrial facility with climate-controlled infrastructure, Industrial Seal Pro™ helps you maintain uptime and efficiency by sealing leaks quickly and safely.

It seals leaks in polyethylene, copper, and steel piping and is fully compatible with all major coolants – including ethylene glycol, propylene glycol, and salt brine. The non-toxic formula is safe for the entire system and won’t clog flow paths or damage sensitive components. It’s also harmless to all plastics, metals (including aluminum), hoses, and fittings – making it a reliable, no-risk solution for maintaining critical cooling and heating infrastructure.

Shaler® Industrial Seal Pro™ Key Benefits

- Seals leaks

- Inhibits formation of rust and scale

- Keeps system clean

- Neutralizes pH imbalance

- Controls electrolysis

- Lubricates coolant pumps

- Compatible with all coolant types and brands

- Conditions and enhances refrigeration/heating system operation

Industrial Sealant Technology

The sealing particles in Industrial Seal Pro™ adhere to the outside of a leak and progressively build inward. When exposed to outside air, the particles harden and expand by roughly 15%, forming a durable, putty-like seal that locks in place – without disrupting system pressure or flow. This allows for on-the-fly leak resolution without interrupting cold storage operations or requiring costly shutdowns.

Pump Seal Lube

Industrial Seal Pro™ includes a built-in water pump seal lubricant that keeps seals clean and prevents leaks from forming. It also contains ultra-fine particles that act like graphite, penetrating between the shaft and seal to reduce friction, eliminate howl and chatter, and extend pump life – all without compromising system integrity.

Coolant Conditioner

Beyond sealing, Industrial Seal Pro™ actively conditions the coolant. It helps prevent the buildup of rust and scale – two of the leading causes of flow restrictions and dead zones. Chemically, it stabilizes pH levels and mitigates corrosion and electrolysis pitting. Mechanically, the particles scrub internal surfaces, improving fluid contact and heat exchange. It also functions like a sacrificial anode, helping protect key system components from internal wear.

Improves Heat Transfer

Clean systems are efficient systems. Industrial Seal Pro™ improves heat transfer by reducing debris and increasing the effective surface area of the circulating coolant. This effect benefits both the chiller loop and floor/space-conditioning loop, with most facilities experiencing a 2.5% gain in thermal efficiency – even in older, high-usage systems.

ASTM D3147 Laboratory Test

Industrial Seal Pro™ has been tested to the standards of ASTM D3147, the recognized test method for evaluating stop-leak additives in cooling systems. This protocol ensures reliable, repeatable assessment of sealing capability, system compatibility, and performance under simulated operational stress. Industrial Seal Pro™ not only meets but exceeds these benchmarks – delivering trusted results in even the most demanding industrial refrigeration environments

| Gum/Gel Before | No |

| Gum/Gel After | No |

| Particles Before | No |

| Particles After | No |

| Screen | 0.51 mm (0.020 inch) |

| Final Round | 0.64 mm (0.025 inch) |

| Final Slot | 0.25 mm (0.010 inch) |

| Fluid Lost, mL | 495 |

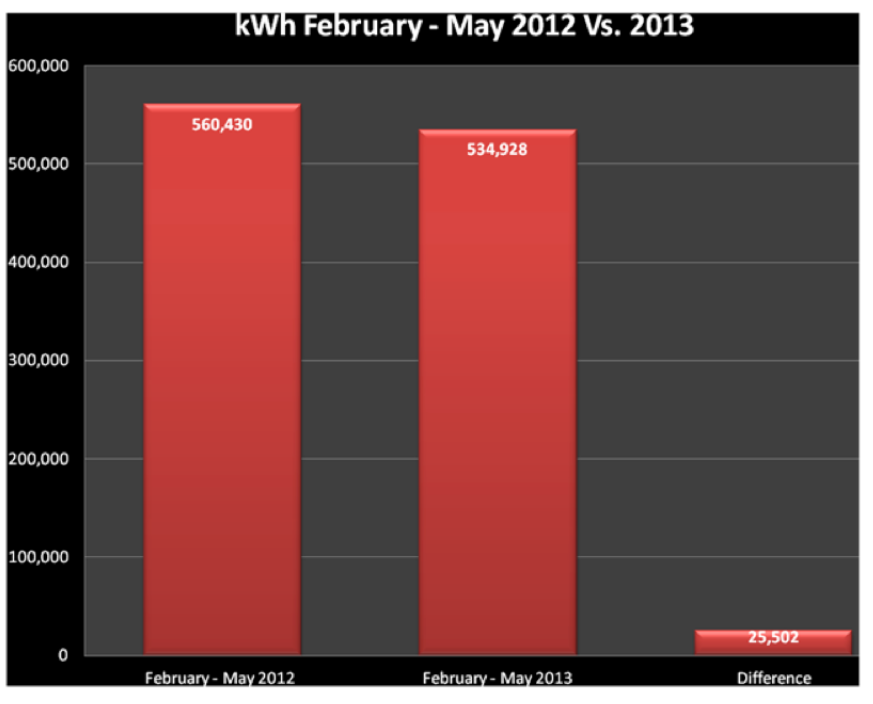

Year-over-Year Energy Consumption (4 Month Period: 2012 vs. 2013)

Despite a 6.9% increase in facility usage across all three ice sheets in 2013, overall energy consumption decreased – demonstrating the measurable efficiency gains achieved after implementing Rink Seal Pro™.

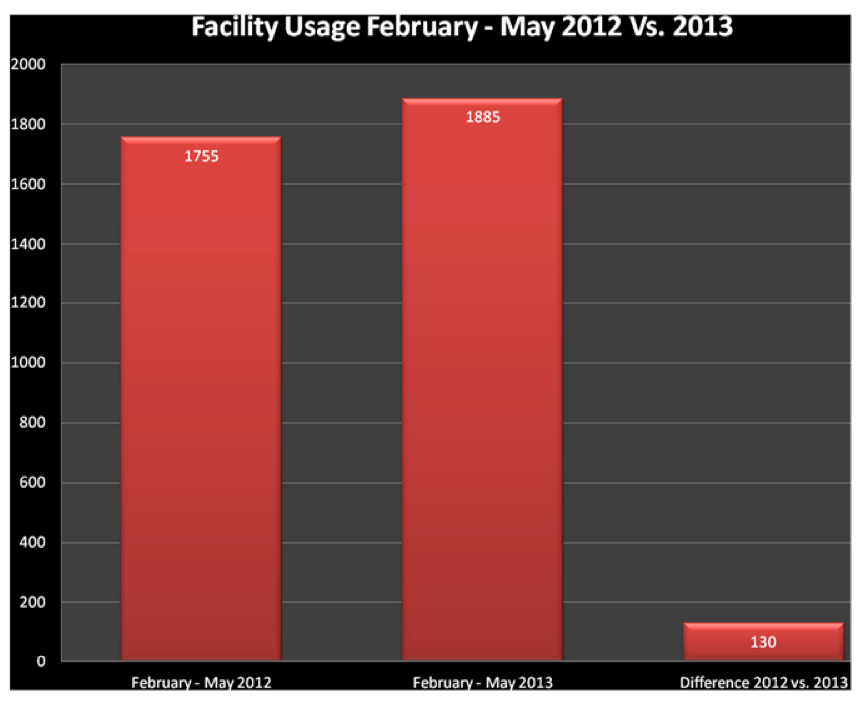

Facility Usage in Hours: 2012 vs. 2013

Even with more hours of operation in 2013, the test facility recorded significant energy cost savings following the installation of Rink Seal Pro™ – a clear indicator of improved system efficiency under increased demand.

Testing confirms that Rink Seal Pro™ can successfully seal leaks as large as a 0.64 mm (0.025 inch) round hole and a 0.25 mm (0.010 inch) wide crack – demonstrating its effectiveness in addressing both pinpoint leaks and narrow fractures common in rink and underfloor systems.